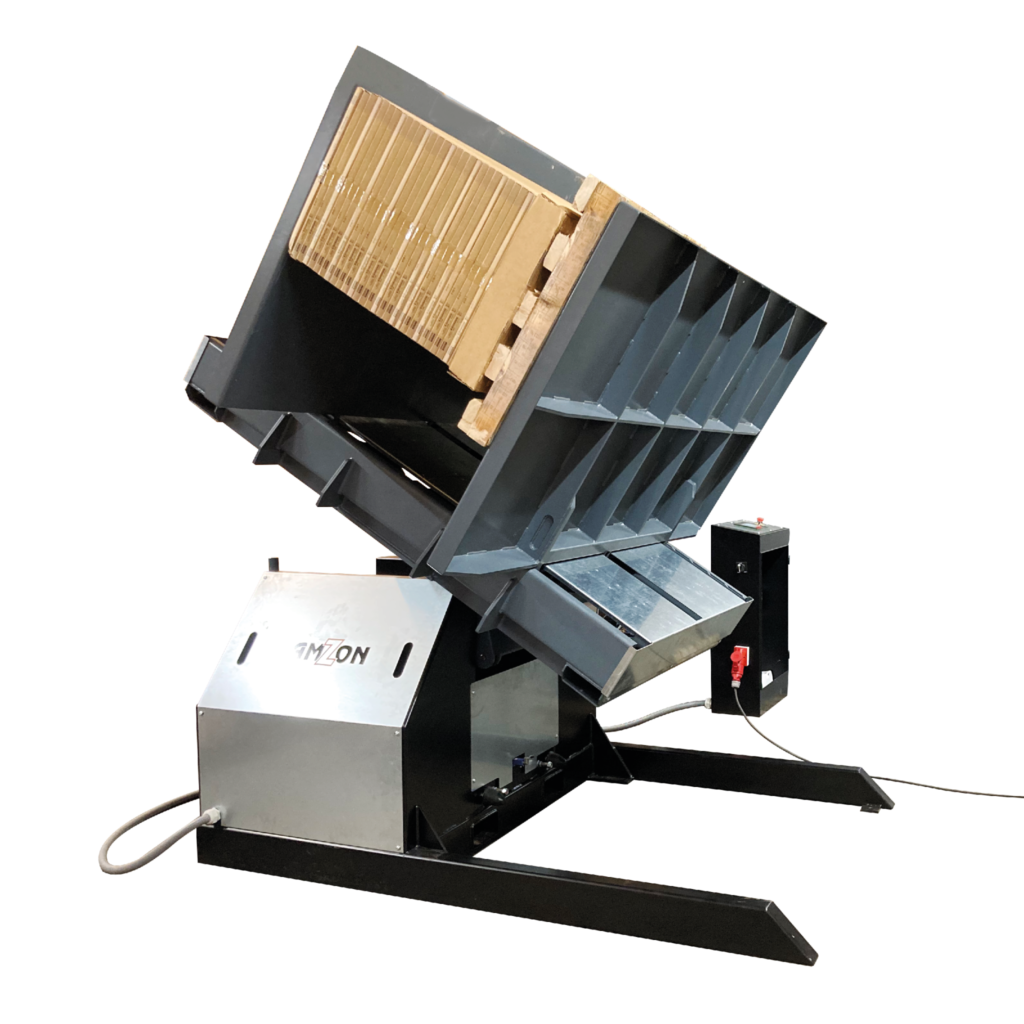

The SAMZON Pile-Turner is a high-performance, stationary machine designed for efficient pallet exchange beneath your products. Engineered for reliability and precision, this model is particularly favored within the paper industry.

Products · Pile Turner

The Samzon Pile-Turner 104L is a stationary machine designed for efficient pallet exchange beneath products, making it an ideal choice in the paper industry. A key advantage is its ability to close down to 320mm, allowing it to handle very low-profile products.

The Samzon Pile-Turner secures the product with platforms, tilts it back 90 degrees, manually rotates 180 degrees, and then lowers and unlocks the platforms, seamlessly placing the product on a new pallet. Pallets are fed into the machine using a pallet truck or jack.

The machine is available with various additional equipment and surface treatment options.

Either scan the QR code below for our brochure on the LVA models, or fill out the information form below, and we’ll get back to you as soon as possible!

The pallet and pile-turner machine is primarily used to switch out damaged products at the bottom of a pallet or to remove spacers from between the products.

By using the pile-turner machine it is possible to tip the products over onto a new pallet or switch out damaged products without having to move all the products manually from one pallet to another.

The necessity to handle heavy products is removed to reduce the amount of work-related injuries and daily wear on coworkers and thereby improve your company HSE.

This machine can also be used for daily replacements of old pallets. However, the new pallet has to be placed manually on top of the products by the operator.

The Pile-Turner is usually smaller in size, compared to the pallet changer, it is less costly and comes with a relatively fast delivery time.

The SAMZON Pile-Turner machine works by moving the pallet back in horisontal and rotating the original pallet 180-degrees, thereby turning the product on its head. Then, the pallet is manually removed from the machine and replaced with a new pallet.

The pile-turner takes slightly longer time to complete a pallet exchange cycle, when compared to the pallet changer, and does require that the product can sustain being turned around.

However, one of the advantage with the pile-turner is that it can be stopped at 90-degrees, allowing the platforms to separate ever so slightly. You can now remove cardboard, paper, or freezer spacers that may be lying in between the products.

The machine comes with both manual control or automatic cycle, and will be able to change up to 30 pallers per hour.

The advantage of using a pallet changer is that you avoid all manual handling of products and pallets when performing a pallet change.

This machine can change approximately 30 pallets an hour and can handle a large variety of products.

The pallet changer can work with manual stage control using buttons, automatic cycles, automatic pallet placement, and an in-line fully automatic assembly line part including a pallet magazine that allows for automatic pallet management.

The in-line solution offers a large amount of tailored, customer-specific solutions to meet your exact needs.

There are lots of options for additional equipment when you order a pile-turner. See below for a selection of our most popular extra equipment including a description of each option.

The advantage in using an automated cycle is that you ensure that the operator only must press the start button on the control panel – the machine the runs through the entire sequence automatically.

This gives the operator time to handle pallets or other tasks in between sequences.

To use the automatic cycle, safety measures are required to ensure personnel cannot get under the machine during a cycle. Safety measures include safety fence and safety light barriers.

We often see that a galvanised surface is chosen for machines in the medico and food industries where products might get in contact with the machine.

It may also be an advantage is the pallet changer is intended to run in moist conditions.

This is a recommended choice if there are no alternative ways of supplying the machine with air.

We attach a small “low-noise” compressor to the pallet changer.

Choosing the external start option, allows the operator to activate the machine using a pull string or external button. This may for instance allow the operator to activate the machine while sitting in their forklift or other vehicles.

It is possible to add safety or warning lights to the pallet changer, which by using various colours will indicate whether the machine is running, has experienced stoppage or needs servicing.

A package with spare parts is often chosen to ensure you have the most necessary spare parts in stock in case of stoppage, allowing for decreased maintenance time.

Stoppage and downtime on machines can be costly because a part of the production chain is broken, leading to loss of income.

A service agreement on your equipment is therefore important to ensure the optimal amount of runtime.

A good service agreement includes no added costs, but helps you save on expenses.

SAMZON A/S offers service and maintenance on your machines and equipment, and as part of your service agreement you always receive:

Unsure about which solution best matches your needs? Fill out this form and we will give you an offer on a machine that is tailored to your requirements, based on the given information.